PLANT FEATURES

-

Plant in compliance

with GMPOur plant operates in accordance with GMP and is experienced in dealing with inspections by the FDA. In keeping with the SOP (Standard Operating Procedure) which is administered by the quality department, we reliably manufacture high-quality APIs in our plant. Our expert knowledge is based on our long-standing company history and a proven track record of experience spanning a period of 70 years. This enables us to be able to fully comply with GMP conditions.

-

A wide range of

operations ensures flexibilityWe manufacture APIs for drugs as our major product as well as APIs for investigational drugs and raw materials for cosmetics. We have a strong focus in manufacturing products on a small scale that require a comparably long synthesis process, and are able to handle a wide range of Production volumes from a few hundred grams to a few tons.

-

Comprehensive support

from research and development to productionTo ensure that our products are used safely, we proactively deliver technical information to our clients during the early stages of development. From trial synthesis to full-scale production and subsequent quality assurance, we handle all matters at our company. This enables us to support our clients immediately to meet their needs.

PLANT DESCRIPTION

| Location | 4-15-19 Hibarigaoka, Zama-city, Kanagawa 252-0003, JAPAN +81-(0)46-251-0948 +81-(0)46-251-0948 +81-(0)46-256-6071 +81-(0)46-256-6071 |

|---|---|

| Site area | 5,870㎡ |

| Activities | Manufacturing of active pharmaceutical ingredients for drugs and medicines Contract manufacturing of active pharmaceutical ingredients for clinical drugs Manufacturing of raw materials for cosmetics |

| Production Volume | From several hundred grams to 3,000 kg per item per year |

PLANT FACILITY

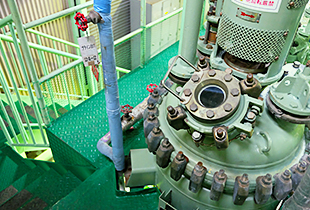

Chemical reactor

| Volume, material etc. | Amount |

|---|---|

| 3000L, glass lining | 1 |

| 2000L, glass lining | 2 |

| 1500L, glass lining | 1 |

| 1000L, glass lining | 3 |

| 500L, glass lining | 2 |

| 300L, glass lining | 2 |

| 200L, glass lining | 1 |

| 100L, glass lining | 1 |

| 2500L, stainless | 1 |

| 2000L, stainless | 2 |

| 1800L, stainless | 1 |

| 1500L, stainless | 1 |

| 1000L, stainless | 2 |

| 800L, stainless | 1 |

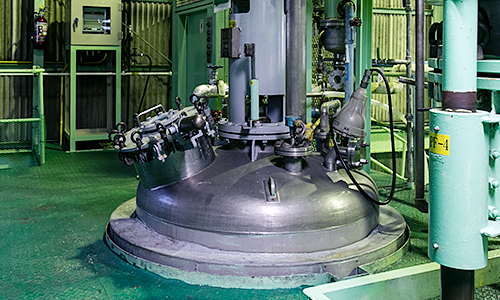

Crystaliser

| Volume, material etc. | Amount |

|---|---|

| 1800L, stainless | 1 |

| 1500L, stainless | 2 |

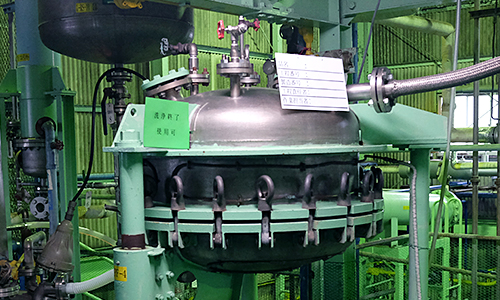

Centrifugal separator

| Volume, material etc. | Amount |

|---|---|

| 42-inch stainless top-expulsion-type | 5 |

| 36-inch stainless top-expulsion-type | 4 |

| 36-inch Hastelloy top-expulsion-type | 1 |

| 36-inch rubber lined top-expulsion-type | 1 |

| 18-inch stainless top-expulsion-type | 1 |

Filter

| Volume, material etc. | Amount |

|---|---|

| Pressurized filter glass lining | 1 |

| Pressurized filter stainless | 4 |

| Leaf filter stainless | 1 |

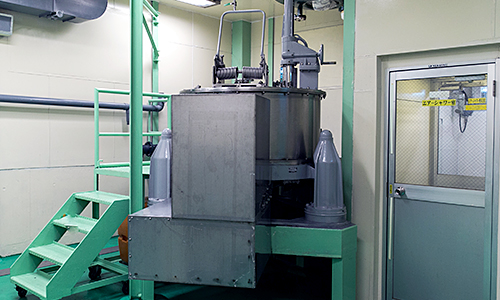

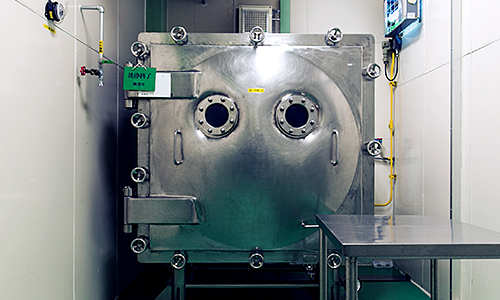

Dryer

| Volume, material etc. | Amount |

|---|---|

| Shelf-type reduced pressure dryer stainless | 5 |

| 800L conical dryer stainless | 1 |

| 500L Nauta dryer stainless | 1 |

| Forced-air dryer stainless | 1 |

Pulveriser

| Volume, material etc. | Amount |

|---|---|

| Cutter mill | 2 |

| Hammer mill | 3 |

| Jet mill | 1 |

Other

| Volume, material etc. | Amount |

|---|---|

| 30kw brine chilling unit (-20°C) | 2 |

| 20kw brine chilling unit (-20°C) | 1 |

| 45kw coolant chilling unit (7°C) | 1 |

| 750, 800kg/h backflow boiler | 1 each |

| Wet scrubber | 5 |

| Waste water processing device | 1 |

CONTACT

Contact us / request documents

Please feel free to send us your enquiry concerning our products and services.

Contact us

Contact us Request documents

Request documents